ABOUT VARICON

Welcome to Varicon Engineering Solutions, your trusted partner in comprehensive mechanical engineering services.

We specialize in Welding, Technologies, Manufacturing, Materials, Testing, Research and Development, and Engineering Simulations, offering tailored solutions to meet your project needs.

Our expertise includes Welding Coordination and Consulting for the companies, Supervision and Inspection, implementation of Welding Technologies, and full support for Welding Projects.

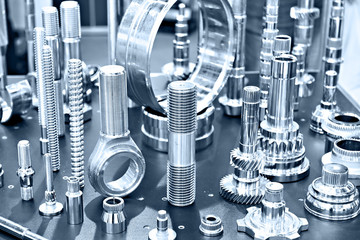

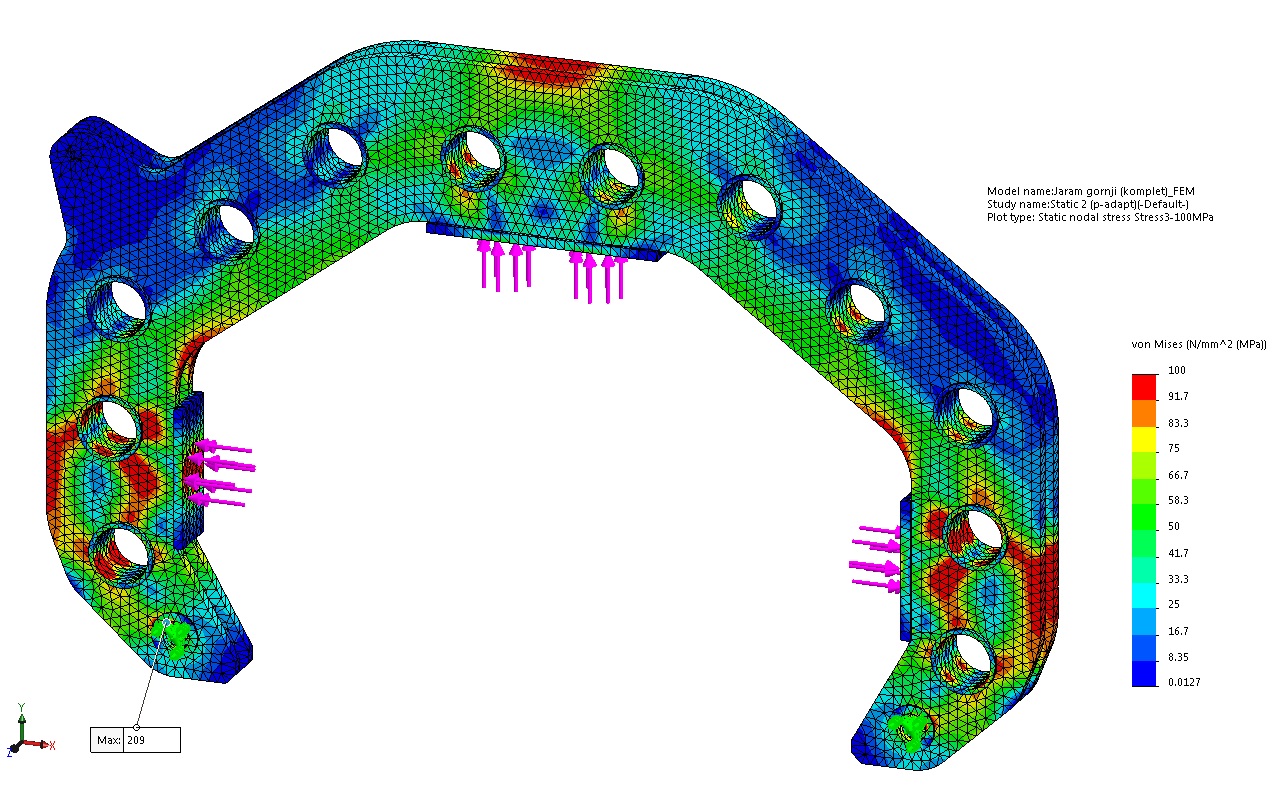

We offer Optimization of existing mechanical parts and structures—covering Design, Manufacturing Processes, Material Selection, and performance enhancement—to improve durability, efficiency, and cost-effectiveness while ensuring compliance with industry standards and project requirements.

We deliver innovative Research and Development for industrial products and machinery, providing complete Turnkey Solutions customized to meet client specifications. This includes detailed CAD Design, CAE Simulations and Testing. Our approaches are designed to improve performance, structural life, and operational efficiency, fostering technological progress and helping our clients maintain a competitive advantage.

Additionally, we provide extensive Materials Testing and structural measurements, as well as Non-destructive evaluation, Failure Analysis, and Quality Assurance services to ensure the integrity, safety, and performance of your engineering components and structures.

Committed to delivering high-quality, cost-effective engineering solutions, our mission is to leverage the latest technology, cutting-edge equipment, extensive knowledge, accumulated expertise, and fruitful collaborations with leading industry, research, and academic partners. By doing so, we aim to help our clients achieve their goals efficiently, reliably, and with competitive advantage in a rapidly evolving technological landscape.

WELDING

Our comprehensive services in welding include:

Welding Coordination / Supervision / Inspection:

Welding Projects:

Welding Research & Development:

We are committed to delivering reliable, efficient, and high-quality welding solutions tailored to your specific needs.

TECHNOLOGIES

Our comprehensive services in technologies include:

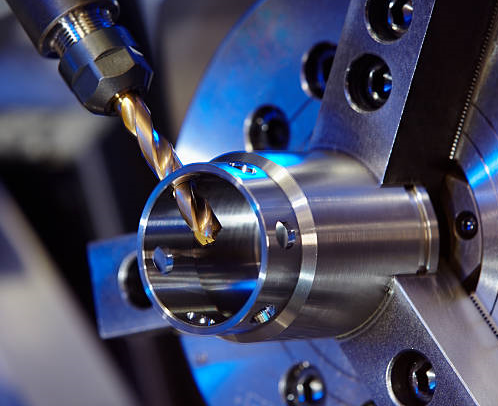

Production Technologies:

Properties Improvement Technologies:

With a focus on delivering innovative and reliable technological solutions, we strive to help clients achieve optimal manufacturing quality and efficiency across diverse industries.

MATERIALS

Our services in materials include:

Metalllic Materials:

Non-Metallic Materials:

Our materials services encompass expert consulting on material selection, optimization of machine parts, and the manufacturing of complete components using carefully chosen materials to meet specific performance requirements.

By collaborating with top material suppliers, we have the capability to procure various grades of metallic and non-metallic materials to meet project specifications.

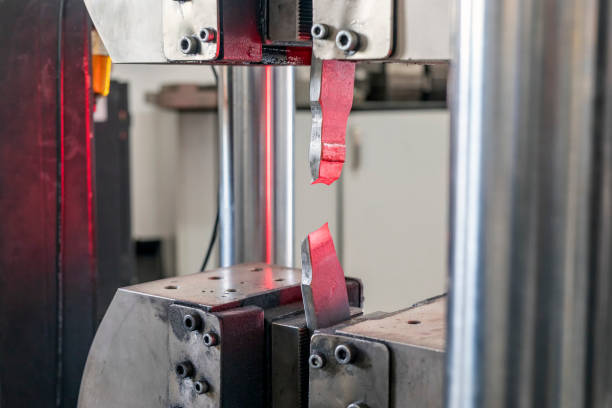

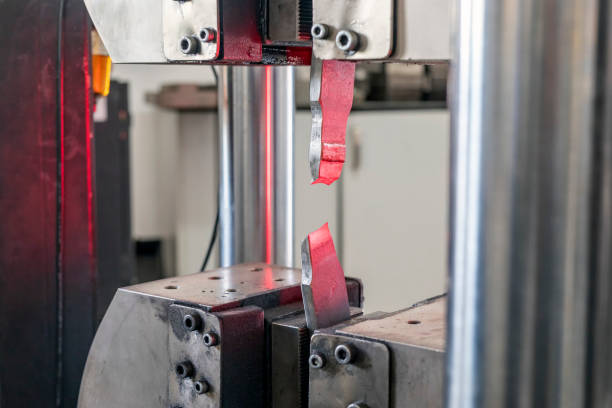

TESTING OF MATERIALS AND COMPONENTS

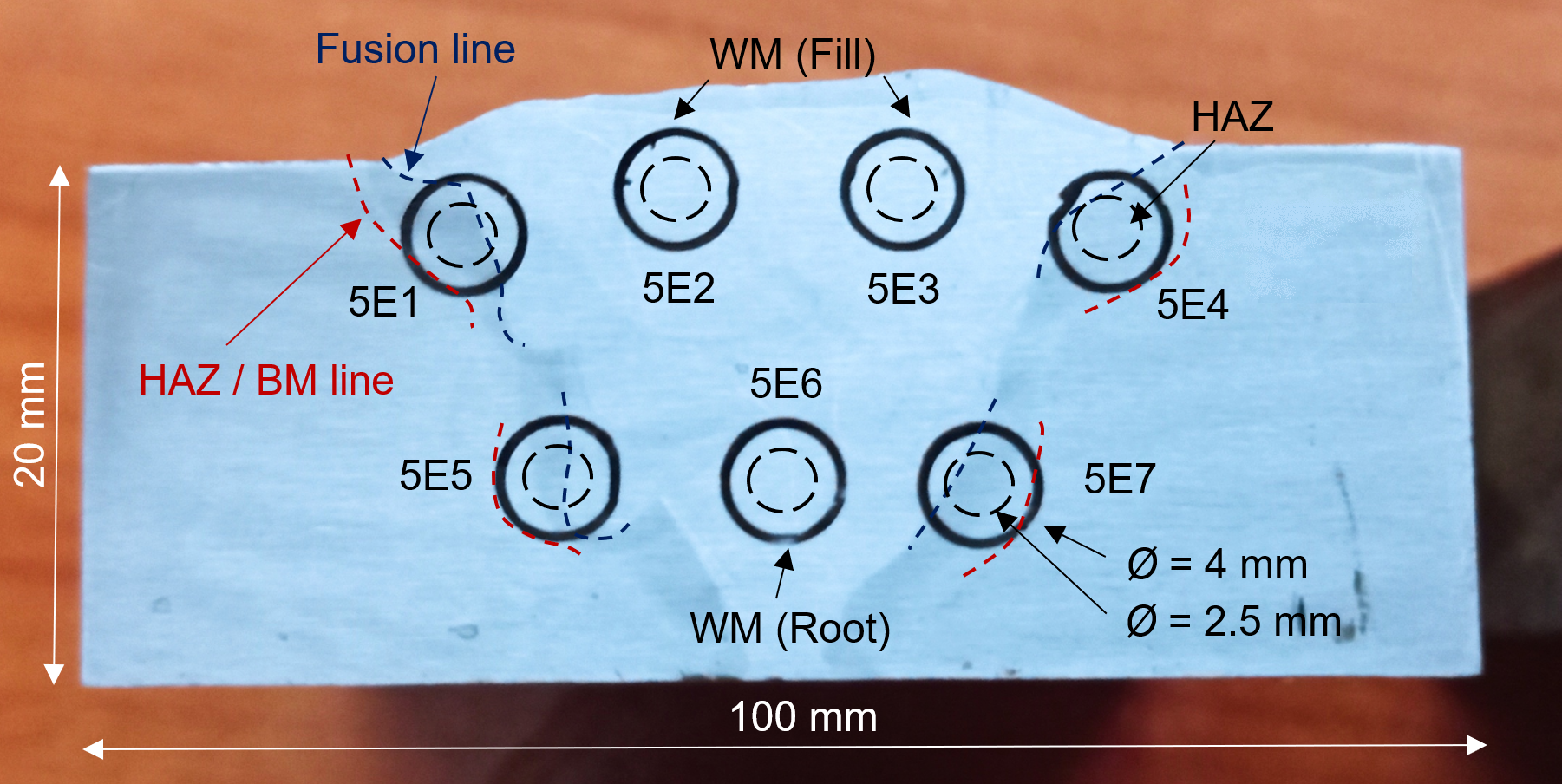

Our services in testing of materials, machine components, structures and welds include:

Monotonic Testing:

Fracture Mechanics and Fatigue Testing:

Macro/Microscopic Analysis:

Structural Testing:

We can deliver a wide range of testing services utilizing our own in-house equipment, complemented by partnerships with prominent domestic and international industrial firms and scientific research organizations.

R&D, PRODUCT DEVELOPMENT AND SIMULATIONS

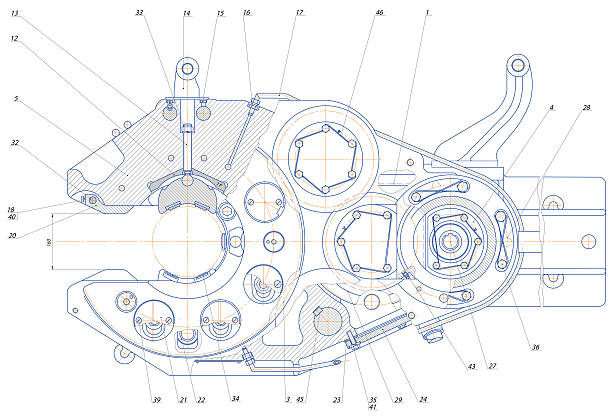

Our comprehensive services in R&D, product development and simulations include:

R&D of Products:

Design and Consulting:

Simulations:

We provide comprehensive R&D and product development services, from concept to prototyping, tailored to client needs. Our offerings include design, 3D modeling, documentation, and simulations to optimize performance. With expert technology support, we deliver efficient, reliable, and market-ready industrial solutions.

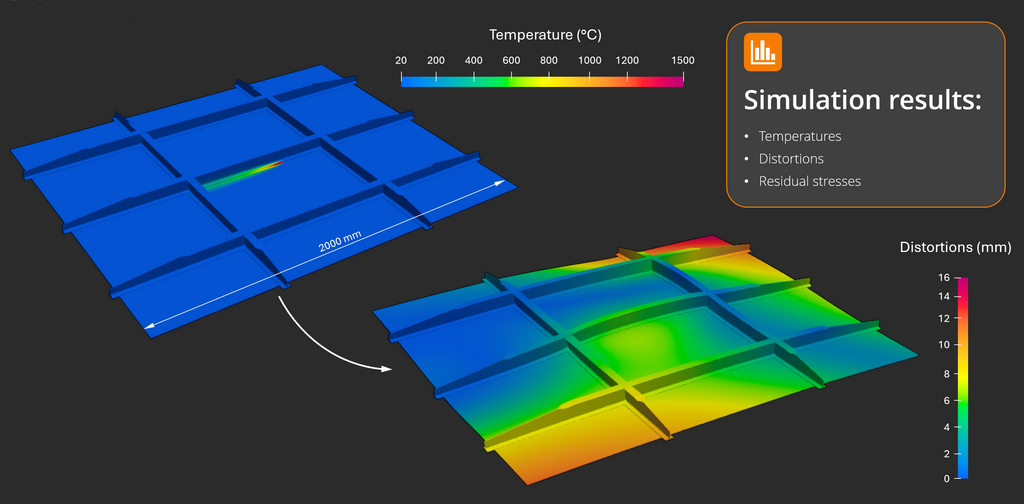

WELDING SIMULATIONS

As an exclusive partner for Croatia and Slovenia, Varicon presents the heatshape, simulation software for Welding, Heat Treatment and Additive Manufacturing.

This approach applies to welding processes in metal structures where unwanted deformations are a concern. It allows for the virtual simulation of structural welding, regardless of complexity, to identify the optimal production strategy. By replacing costly physical testing on actual components, the simulation of thermal processes offers a cost-effective solution, resulting in substantial savings while ensuring accurate assessment and process optimization.

The software capabilities:

The benefits of applying the software in production:

In addition to the heatshape software solution itself, we also offer a complete service for evaluating welded structures with the aim of optimizing their production.

More to be found on the official website:

WELDING PROJECT for TŽV GREDELJ

Project included:

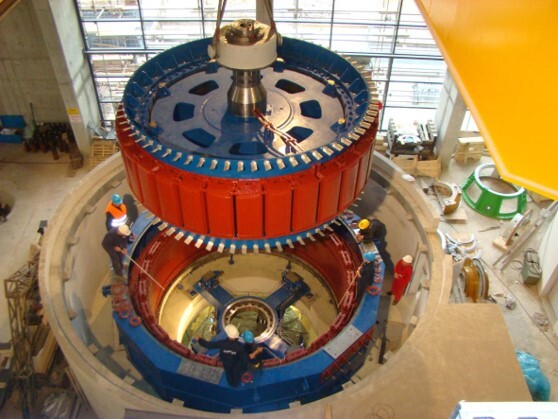

WELDING COORDINATION for KONČAR GENERATORS AND MOTORS

Project included:

Contact us using this form and let's start working together today.